FEATURE INTERVIEW

Interview with BAHADIR BASDERE

I believe that we are facing the most exciting, but also the most challenging times. However, it is a positive challenge.

Transformer Technology hosted the President of Trench Group, which is composed by Trench and HSP. In this interview, we talk to Dr. Bahadir Basdere about REGENERA™ initiative, because it is all about the three Ds–Decentralization, Decarbonization and Digitalization of the industry.

Alan Ross

My guest in this interview is Dr. Bahadir Basdere. What is your role at Trench & HSP?

Bahadir Basdere

I have two major roles. I have the role as President of Trench group, which consists of the different Trench entities around the globe, as well as HSP, our dry type bushing business.

Secondly, I also represent the shareholder Siemens Energy for the entire Trench Group.

AR

We're going to talk about your REGENERA™ initiative, because it is all about the three D’s - Decentralization, Decarbonization and Digitalization of the industry. But before we get to that, could you talk to me about where you think we are in the power industry as a whole?

BB

I believe that we are facing the most exciting, but also the most challenging times. However, I would say that it is a positive challenge. If you think back to 2008 when we had the financial crisis, or a little bit after that, we were faced with a significant decrease of demand and overcapacities in the power industry. We went through more than a decade of coping with those challenges. Now it's the total opposite. We have a HUGE demand.

I see it this way, one of the few positive effects of COVID were the financial grants for all the renewable programs the governments launched. On top of that, the political situation that we currently have in Europe, the war between Russia and Ukraine is now the booster for quickly diversifying and decentralizing power generation. Also, when we look at the biggest challenge of mankind, it is Decarbonization. And for me, these things go hand-in-hand. Digitalization is an enabler to speed up decentralisation and decarbonisation.

AR

Great! So we have the three D’s - Decentralization, Decarbonization and Digitalization – but also Diversification. I agree with you that these are the most challenging, but also the most exciting times.

As President of Trench Group & HSP, let’s talk about the vision and the mission of the organization of which REGENERA™ is also a part. What are you trying to accomplish?

BB

Our mission is to support our customers in decarbonising the world with their equipment, and with their products and projects that they acquire from us. This is a clear mission, and we have a clear target. We would like to be able to offer our customers a 100% CO2 neutral portfolio by 2030. I believe we are leading the industry here when we look at our portfolio on bushings, instrument transformers and coils and specifically at the innovations that we are driving.

When we look at the biggest challenge of mankind, it is Decarbonization. And for me, these things go hand-in-hand. Digitalization is an enabler to speed up decentralisation and decarbonisation.

AR

With you and I being in the power industry, we understand the challenges of reducing CO2. When you look at the entire system, where are the areas that you think you could focus on, to be able to accomplish this, at least in the short-term?

BB

It starts from the design. Very simple. You need to consider environmental aspects in the design phase. You reduce material and you reduce hazardous substances that do harm to the environment, such as SF6 or mineral oil. Then it goes over to production, where we have a lot of initiatives to reduce our CO2 footprint. For instance, we’ve switched to green electricity, installed PV on our factory buildings and optimized heating and lightning. These changes can significantly reduce CO2 footprint, and at the same time give you a cost advantage. So, if you consume less energy, you pay less for your energy bill.

AR

Everything that we do begins in the design phase. You said something that I think is very important, which is, you practice what you preach. You put solar into play. You began to do the very things that we ask our customers to do, which is kudos to the company for making those kinds of decisions because it leads the way. We have to lead the way. As you said, these are challenging times, but exciting times because there are problems, we know we can solve. We know we have the time now to solve it.

I know this is a little off topic, but how has the situation between Russia and the Ukraine affected the REGENERA™ program?

BB

It is a boost for us now in particular when we look at the product part of REGENERA™. For instrument transformers, we are providing the whole range of VT’s and CT’s up to 800 KV in SF6-free insulation – I am talking about Clean Air as a gas which is in fact nitrogen. We are also providing Ester fluid solutions. Therefore, we see a huge demand. We see big TSO’s in Europe really becoming active, issuing RFQs where a certain portion of their system already requires them to be free of hazardous substances.

We also have regulation by the European Union that will significantly reduce F gas in electrical high voltage products. This is a booster too, and of course being one of the few ones offering the whole bandwidth of the portfolio is nice. But this brings us to another challenge. Now, we need to have competitors in the market who are at least offering similar products as we are, so that when demand explodes, customers can have an effective risk-mitigation strategy. Understandably, they cannot be dependent on one supplier for this equipment and technology.

AR

Kudos to you to see it that way; nobody can do this alone. That's the one thing that I walked away from this conference saying, there's nobody that's got the one answer.

The important thing is to develop new technologies and new approaches. So, for instance, getting rid of SF6 gas, that's an industry-wide problem that needs an industry-wide answer. So how do you share technology with your peer competitors, without sharing your secrets to success?

BB

Great question, and I really do see them as peers because no one is able to serve this huge market alone. To answer your question, I must highlight that we do not share our technology. However, we do have exchanges with our peers on a regular basis on topics like industry standards or what is needed to foster green technology. In general, I would say it is an exchange on a higher, technical level

You may even see partnerships in the industry. We’ve seen that happen. I think it's absolutely important that this exchange with peers takes place to make sure that we go in the right direction. Because at the end of the day, what we need is speed and as you said, we can only have speed and results if we all move in the same direction. Our customers want to have a standardized solution, and they cannot cope with multiple approaches.

Our mission is to support our customers in decarbonising the world with their equipment, and with their products and projects that they acquire from us. We would like to be able to offer our customers a 100% CO2 neutral portfolio by 2030.

AR

Somebody once said, and I told the person that said this that I was going to steal it, and I'm stealing it now. If you want to go fast, go alone. If you want to go far, go together.

BB

That's right.

AR

What we have to do now is unbelievable. We have to go far, fast. We must get there a lot quicker.

You mentioned something I want to go back to. You have all these initiatives, but you have a lot of suppliers. I mean, you don't magically make bushings and instrument transformers. You bring all these suppliers in. Are you putting in place supplier covenants that ensure that your suppliers are also managing the four D’s? Particularly Decarbonization. Is that something that you're bringing them along with? Because that's going far and it's going fast.

BB

Absolutely, Alan, and on that point: we have started doing Lifecycle Assessments for our products, which is a very important tool. It is where we consider the CO2 footprint of our suppliers, of the components being supplied. We also audit them on environmental aspects which is a clear focus of ours. It is our aim to incorporate the results of lifecycle assessments also in the new development phase of future products and solutions.

AR

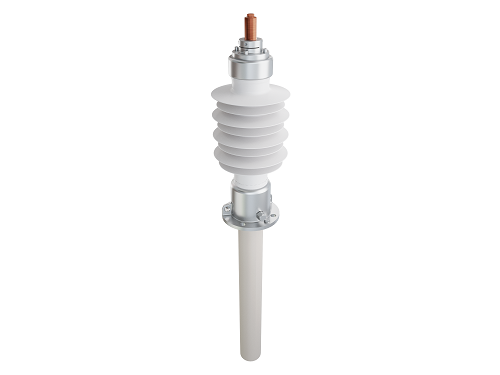

I would have to say that bushings are a major component of transformers. I think recent research that I read was that 52% of transformer failures were bushing failures. Nine times out of ten, it is due to aging. However, it is safe to say that bushing technology is changing rapidly. How are you all advancing bushing technology as part of this whole REGENERA™ initiative?

BB

In bushings we have to distinguish between oil- and resin impregnated bushings.

On the oil immersed bushings side, we are fostering the shift to ester fluids instead of mineral oil. This not only has a positive contribution to the environment, it also comes with significant technical advantages on aging and safety, e.g., the higher flame point of ester fluids is reducing the risk of fire hazards substantially.

On the dry-type bushings side, we are rapidly changing from RIP (resin impregnated paper) to RIS (resin impregnated synthetics) technology. With this, we are giving our customers a reliable, easily storable and environmentally friendly product.

And, Digitalization also plays an important role in this transformation – that is why we are offering our customers our SensbushingTM Technology. With this sensor-based solution, they are always informed about the status and performance of the bushing in real-time. This helps to extend the lifetime of the product and avoids faults.

AR

Excellent, because I think small changes everywhere make big changes. I've got two more questions for you. One of them is about when you talked about instrument transformers, and you talked about some of the other technologies that you all are working on. Solid state is replacing mechanical in the world, right? Talk to me a little about the initiatives that REGENERA™ has around Solid-State technology.

BB

As solid state – I would also consider alternatives, like optical- and nonconventional instrument transformers. With our optical current transformers, we are already able to serve the market up to 800kV.

The key in this case is standardization – the optical measuring device could handle a huge variance of Voltage Levels – therefore it is an absolute advantage for our customer, keeping just one product on stock for different voltage applications.

Beside this and other benefits, the digital system can measure network information that can currently only be collected with additional effort.

Things are moving fast now, and we see very positive response from our customers.

AR

My last question for you which you've kind of answered already. You launched REGENERA™, and you created this initiative around the four D’s. My question then is how do you get the entire company to get excited about this?

BB

Trench and HSP are brands with deep roots. E.g., Tony Trench built the first coil in 1962, and over the years Trench has been acquiring companies that have been in this industry for more than 100 years. Employees and customers alike have a very strong bond with these brands. Some of our people have been working for us for over 50 years but we also attach great importance to bringing new energy to the company and therefore we invest in human resources. With this in mind, we have recently repositioned both brands and redefined our vision, mission, and values to give them an experience-based and strongly future-oriented perspective, each according to their own strengths.

Our team is completely behind us on this, and we did not face a lot of reluctance with our employees because they see it as a chance for change and a way to be involved in our transition to a greener future.

AR

Thank you so much for this interview, and I really love what you're doing at Trench Group.

BB

Thank you.