FEATURE INTERVIEW

Interview with SETH JOHNSON

VICE PRESIDENT AT POWERSIDE

Ultimately, I believe technology is always going to get better, but is it going to be good enough to maintain the stability required for an optimal high functioning power system? That's where I think our business plays in, and that's where we have our play in the market.

Alan Ross

We're at Distributech 2023. My next interview was with Seth Johnson. He's a Vice President at Powerside. Welcome. Thank you.

Seth Johnson

Thank you for having me.

AR

Tell me a little bit about your career, how you got into this industry, and how you got to Powerside.

SJ

Yeah, it's been an interesting road. I actually never had a desire to get into the Power Systems industry.

I studied psychology and got a degree in psychology and business. And then my goal was to go into neuroscience. I started a PhD program in neuroscience, worked in research for several years and decided it was not for me. I had a family member who worked in the power industry. They were a manufacturer sales rep. in Minneapolis, which is where I grew up, and I spent about four years working for them. They hired me as a technical sales rep, and I got in and just started absorbing everything. I'm in the power business now, and it's addictive.

AR

You're of the generation, Seth, that wants to know that they're making a difference. That's how we're attracting people now, not because they're about pay and the fact that we're a pretty secure industry. You're making a difference. You probably use psychology when you talk to your customers to understand what they think or how they think or what they do. I want to talk about Powerside, because obviously now you're a VP. Explain what it is that you do with the company.

SJ

I'm a Vice President and General Manager of our Corrections Business division. At Powerside we have two different divisions, one in Montreal and one in Alameda, California, two different product lines. We're the same company, but I manage everything that happens out of the Montreal business, which is our power corrections business. When we find power quality issues and they need to be corrected, that's where the equipment gets manufactured.

AR

I was the president of EPRA, the Electric Power Reliability Alliance, before I retired. The changes that are going on that we're trying to adopt or adapt to in this industry, resiliency, reliability, safety, are creating more power quality issues. Talk about the problem and then we're going to talk about Powerside’s solution to it.

SJ

Sure. The problem is it's an ongoing challenge. I mean, we have all these distributed energy resources now that are contributing power to the grid. We're at a point in time where being able to understand what's actually happening on the grid, how power is being used, how it's being produced, how it's being consumed, and how it's being stored, which is so critical to the infrastructure that we have in general.

The problem essentially is that we’re transitioning from coal-fired power plants, high inertia generation, and we're using transistor-based technology, or inverter-based technology to essentially create this AC sine wave back onto the system. Doing this at small scale, people didn't really think much of it because it didn't do a whole lot, but now you're seeing large amounts of it. When you think about how energy is being produced and consumed and then stored, as we get into DC micro grids and energy storage the problem is that these power sources rely on inverter-based technology. You're using high frequency switching to create this sine wave to bring power onto the network, which is creating noise on the distribution grid.

AR

It's interesting, we did some interviews at the Re +, which is a conference in Anaheim, and one of the things that came up was how the whole grid being inverter-based technology is affecting the assets themselves. In addition to power quality, transformers are not lasting as long as they did because they're not used to various power sources, and historically only to step down voltage, right? Not step everywhere! You can give it, you can take it. It's kind of a mess in there. The impact of power quality, let's say, on the end user; whether that is; let's deal with residential first and then I want to talk about how data centers might be impacted, how industrial plants might be impacted, but what is the actual impact of bad or poor power quality in a residential environment?

SJ

When you think about it from a residential standpoint, essentially, we're losing inertia on the grid, which is what creates the frequency tolerances in which we run the system. When you have all these PV applications that are contributing, you might have enough power available, but if there's a big inrush, or a large motor load, it might not be able to sustain the voltage, and it might also shift the frequency. With the amount of inverter-based technology in the modern electrical system, adding solar increases harmonic content, which is a multiple of the fundamental frequency that is present. This happens with any kind of high frequency switching devices. Harmonic content is dissipated as heat in the system, fundamentally. You think about it from your conductors inside of your home to the conductors going to the transformer, and now you have all of this heat, and then you think, what is the long-term effect of this? If we have, for instance, high harmonic distortion in a residential network, which could also be the same in commercial, or industrial electrical network.

AR

In the data center market, it's absolutely imperative that they have clean power. A lot of industrial applications now use robotics. Robotics are impacted by bad power quality. We hear that a lot, that the industrial power quality issues are growing. In 2001 EPRI did a projection by the next decade. We've already passed that time. The dollar loss of power quality issues in industrial America was somewhere around $50 billion annually. It's a lot of money that industry is going to lose, and they have to be competitive. How does Powerside deal with that problem?

SJ

You made an interesting point there. Go back 30, 40 years, where you have these big induction motors, at heavy industrial facilities doing various production process. It was all induction-based motors, transformer-based welding. Now it's inverter-based welders, you have variable speed drives, variable frequency drives, DC drives, all of that stuff which is controlling motors. All of that allows the motor to become a little bit smarter. But it creates another issue, which is, again, this harmonic content on the network.

The other thing that's really interesting is high frequency emissions. These are high-frequency noises that are in the bandwidth of 9 to 150 kHz. We did a study at a plastic extrusion facility, and they had a 10 kHz voltage of around 25 volts, so it's this very, very high frequency voltage, which nobody can really pick up.

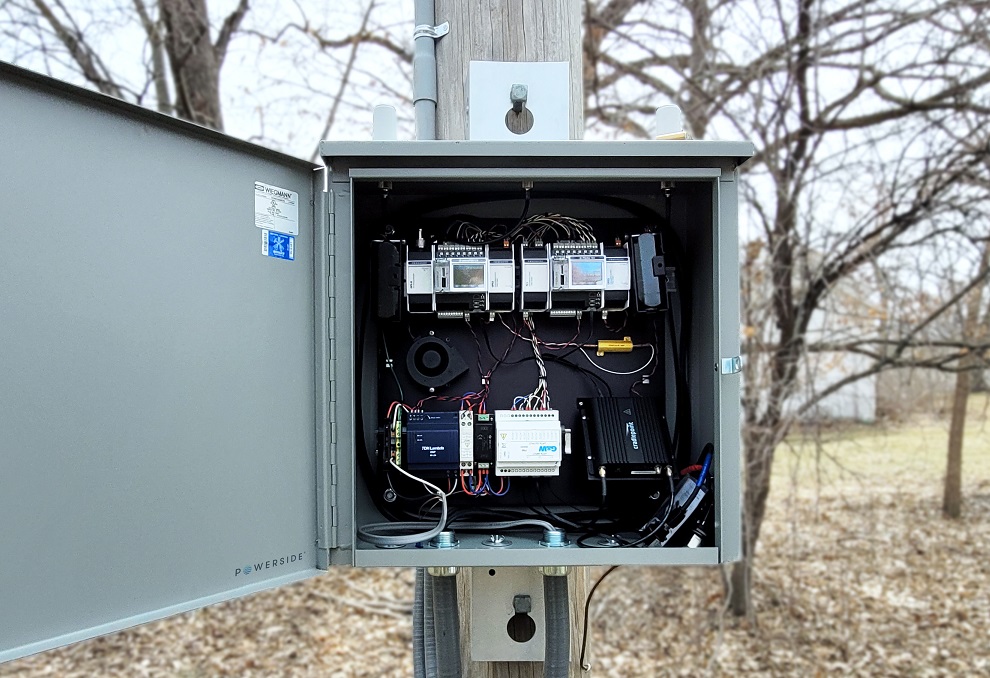

The good news is, in many cases, it gets dissipated. It typically can't flow through the transformer back onto the grid. The downside is that communication and control systems can be greatly affected. The circuit boards are frying, capacitors are blowing up in the control boards. We actually manufacture a very high-end power quality monitoring device, which does waveform capture, waveform sampling. We can do high frequency emission testing, looking at those very high-frequency voltages, and then on my side of the business, we do the correction. We have a power system analysis program where we'll go get data in the field, and then come up with a solution. We're using active harmonic filters, passive filters, and capacitor banks for power factor correction, and we'll even do high pass filters for supra harmonics, these high frequency noises that pose themselves as issues in distribution grids.

AR

One of the issues that everybody is having, whether you're a supplier to the industry or whether you are the utility industry, is labor. That's from everything, the unskilled technician to the skilled tech, skilled trades linemen. You have the detection and the correction. How can it help the labor shortage or how can it help the people in the company work better, work smarter, work faster? In the detection, you got to be using input from the people in the company. How are you helping them do their jobs better?

SJ

For general industry, it's about equipment uptime, when we get into the correction side of things. But we can't do that unless we can detect what the problem is. From a process perspective, our goal is certainly to improve efficiency of these facilities and decrease waste. When we do power factor correction, we're able to decrease current consumption and improve the efficiency of the power system, which will also improve the integrity of the system long-term. When we're talking about harmonics, how they might perpetuate through the electrical system, and how they can be damaging to electrical equipment, you could see how a lot of consumers may not have the expertise to understand this power quality phenomenon.

That plastic extrusion facility I was telling you about, replaces all their drives every three weeks. This is millions of dollars a year! When you can go in with a solution and say: No, this is your issue, this is where it's at and this is how we can fix it; you're a hero in that scenario. We're not an engineering services company, but we provide a lot of very specific knowledge for specific applications.

Essentially, this smart grid is going to be the future. For example, the utility is going to know your car is plugged into the wall, so if they need to supplement power somewhere else, they'll have the ability pull power out of your vehicle, or whatever other energy storage device is connected to the grid.