Image for illustrative purposes

Ultimately, what gives confidence to customers about new technologies like ester fluids is the field experience and condition monitoring.

Introduction: Dielectric fluid or oil is a critical component in an oil-filled transformer – be it power, distribution, or any special transformers, reactors, or switchgear. As the name implies, the main job of dielectric fluid is to provide liquid insulation. The major functions and characteristics of oil are the following:

- Provide good liquid insulation to all conducting parts in a transformer

-

Impregnate paper insulation by filling the voids effectively to remove air bubbles

-

Function as a coolant

-

Good chemical stability during the lifetime of a transformer

-

Inert to materials used in a transformer

-

Act as the information carrier on the health of a transformer

-

Should comply with HSE requirements (HSE stands for health, safety, and environment

Therefore, it is extremely important to select the right oil for the right end application. The following major oil types are currently established technically and commercially:

1. Mineral Oils, the major workhorse of the industry (Both paraffinic and Naphthenic)

2. Environmentally friendly, biodegradable, and fire-safe Ester oils for specialty applications (Both Natural ester & Synthetic ester) for all applications especially for renewable energy projects like floating solar & Wind Power etc.

3. Silicone Oils with limited scope for applications

4. New, emerging specialized oils (e.g., Bio-based oils and Gas-to-Liquid oils)

Savita Oil Technologies Limited (SOTL) has a large portfolio of transformer oils covering the first two categories of oils.

Mineral oil-based transformer oils in Savita Oil Technologies Ltd (SOTL)

Technology developments in Savita kept pace with the progress made globally in the field of transformer Oils. Here's how technological evolutions have taken place in the field of transformer oils.

Historically, Naphthenic oils were popular in Europe and the USA due to the ready availability of Naphthenic crude-based base oils and it continues to be so even today. However, in South Asia and Southeast Asia, Paraffinic Oils are being used predominantly due to technical reasons relevant to the warm climate in these regions. The warm climate meant that low-temperature properties such as pour point and viscosity at subzero temperatures are largely irrelevant for this region. The technical reason coupled with more readily available paraffinic crude-based base oils gave impetus for the oil technology companies such as Savita Oil Technologies (SOTL) to carry out extensive research to develop paraffinic-based transformer oils in addition to Naphthenic transformer oils.

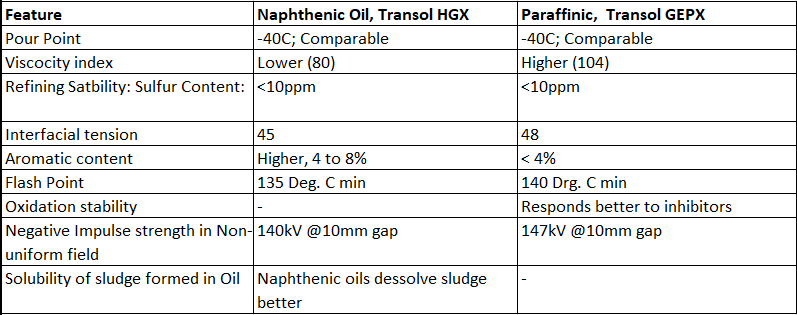

In the initial decades of the mid-1960s and 1970s, paraffinic transformer oils, though suitable for Asian conditions, were considered inferior in Europe and the USA where low-temperature properties are essential. However, continuous research and technology developments over the decades in oil refineries globally enabled SOTL to develop high-quality Paraffinic oils that are on par with naphthenic oils in all respects with only minor, insignificant differences in properties and function. SOTL’s paraffinic oils meet all the international standards such as IEC (Highgrade, inhibited, uninhibited) or IEEE, ASTM, and several national standards. Here’s table 1 highlighting important properties of present-day paraffinic oils and Naphthenic oils produced by SOTL:

As one can see from the table, there is very little to choose between a paraffinic and a Naphthenic oil. Most of the properties are comparable. Differences, when they arise, are not significant to make a difference in the performance of a transformer.

Having said that, Savita offers both types of oils and leaves the final choice to the end user.

Significantly, Transol GEPX (Paraffinic) is time-tested for even EHV applications, e.g. 400 kV class. Savita’s Naphthenic grade transformer Oil, Transol, is, of course, used widely for all applications involving 765 kV class and also for demanding applications of HVDC transformers.

Transol products are further supported by technical services backed by Savita’s oil condition monitoring expertise. Needless to say, dielectric fluids require expert advice on usage and condition monitoring, both of which are provided by Savita.

In summary, Savita’s portfolio of products based on mineral oils (TRANSOL brand products) fluids satisfy the three D’s of performance criteria for transformer applications:

-Durability

-Dependability and

-Delivery of performance at an optimum cost

Ester Technology Developments at SOTL:

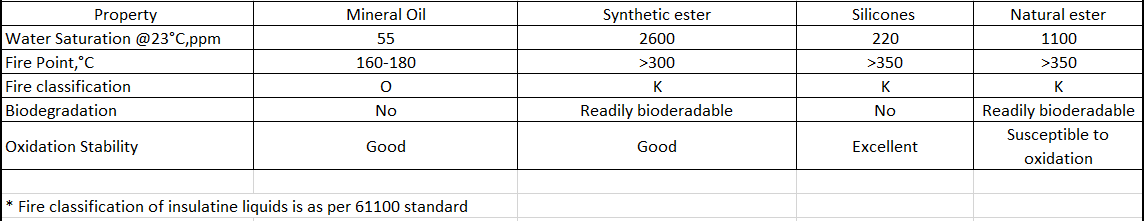

The ester fluids technology of Savita is yet another landmark development that has taken place in the past decade in Savita. Savita’s Natural ester product, Biotransol, is backed by a process patent. Esters offer unique advantages over mineral oils in certain areas of application. A comparison of the properties of ester oils with mineral oils is shown in table 2.

It is clear from the table that the ester oils score over mineral oils concerning fire class and biodegradability. These two properties ensure superior fire safety (being a K-class fluid) and environmental friendliness respectively for ester oils over mineral oils.

Besides the above advantages, the higher water saturation of ester oils compared to mineral oils (see the above table for comparison) means more tolerance of ester oils to moisture in a transformer. This translates to slower aging of paper insulation in ester oils compared to mineral oils as explained below

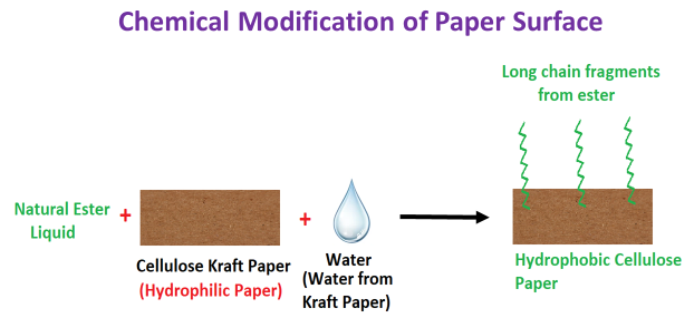

In a landmark paper, presented by the Savita research team at the prestigious international conference in Rome in 2019(International Conference on Dielectric Liquids), spectroscopic evidence (XPS & FTIR) was presented to show how a Natural Ester Oil, Biotransol, interacts with cellulose polymer (paper insulation) to slow down aging and enhance paper life. A simplistic representation of how it is achieved by a Natural ester is depicted in figure 1.

The paper describes how a natural ester oil (e.g., bioTRANSOL) chemically modifies paper insulation to produce a hydrophobic paper. In effect, the paper surface would repel water which can otherwise cause paper degradation. The hydrophobic protection of the paper surface is provided by Natural ester oil and this accounts for the slow aging of the paper insulation. This phenomenon was not found to be occurring with mineral oil under the same conditions as our study.

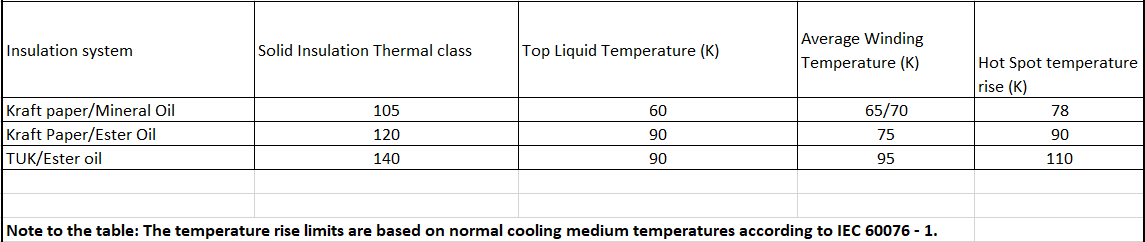

The slow aging of paper insulation in ester oils has resulted in IEC standards allowing higher temperature rises for ester-filled transformers compared to mineral oil-filled transformers.

Using this standard, an end-user can leverage the higher temperature allowance to either operate an ester-filled transformer at higher loading than a mineral oil-filled transformer or operate at a similar loading and get better asset life due to its slow aging effect. Table 3 gives the temperature rises allowed by the IEC standard IEC 60076 -14(2013).

Field Experience & Condition Monitoring

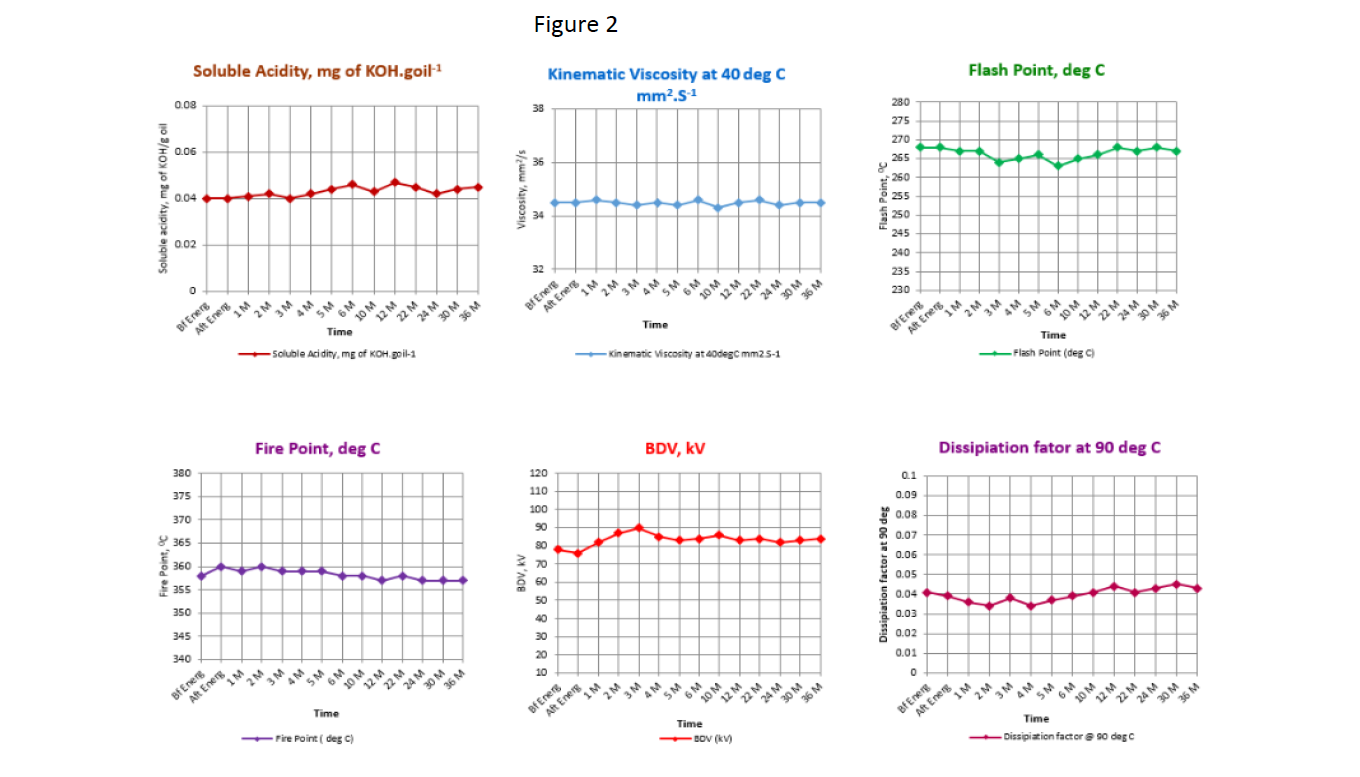

Ultimately, what gives confidence to customers about new technologies like ester fluids is the field experience and condition monitoring. Figure 2 is a representative graph showing condition monitoring data of Biotransol Natural ester-filled transformers carried out over more than 3 years (and continuing) for a prestigious Utility for their 72.5kV class power transformers.

As can be seen from the above plots, the dielectric and chemical properties of the Natural ester oil (Biotransol) have virtually remained unaffected over the 3 years of our study.

Savita’s Transol Synth 100 is being used successfully for distribution transformers, achieving the desired objectives of biodegradability, and fire safety combined with very good oxidation stability.

Retrofilling aged mineral oil-filled transformers with ester Oils – A New Trend in Technology:

Retrofilling refers to changing aged oil from an old transformer with a new oil when the oil has degraded to a point where it cannot be reclaimed. Ester liquids are increasingly being used for retrofill applications.

Objectives of retrofilling with an ester liquid

Retrofilling with esters has the following general objectives:

1. Enhancing fire safety of the transformer and upgradation of the fire classification from class O to class K. Additional expected benefit is the biodegradability of the new oil.

2. Enhancing the life of the paper and hence of the transformer asset

3. The third objective could be to enable the user to operate the transformer at 10% higher than the originally rated load without affecting the life of the transformer asset.

General Process followed for retrofill in brief:

Firstly, the old oil needs to be removed from the transformer as much as possible. It is virtually impossible to drain out the old oil completely. However, the residual oil sticking to the paper insulation will have to be flushed out using a small portion of the ester liquid. The flushing operation should be carried out once or twice. The objective is to make sure that the contamination of the ester liquid with the old mineral oil is no more than 7 to 10%. It is important to stick to this limit since any higher level of contamination of the ester liquid with the mineral oil will result in a fall of fire point below 300°C and hence will not qualify to be called a K-class liquid.

If the mineral oil-filled transformer is of free-breathing design, the retrofilled transformer with the natural ester will have to be sealed by adding a conservator and a rubber bag. This precaution is, however, not necessary if the alternative liquid is a synthetic ester. This is due to the higher oxidation stability of a synthetic ester liquid compared to a natural ester liquid. However, it is important to check the compatibility of ester liquids with the gaskets already fitted in mineral oil-filled transformer.

Savita’s Natural ester Biotransol has been popular in India for retrofil projects, having completed several retrofils successfully. All these projects are being monitored closely by the technical team of Savita to ensure that the objectives of retrofil are fulfilled.

Conclusions:

The selection of a transformer fluid type depends upon the objectives dictated by the end user. However, once the right type of fluid is selected, the choice of a vendor is extremely important. Savita is a preferred vendor because of the following reasons:

-

Decades of experience in the field of manufacturing, research, marketing, and technical services which are backed by a strong R&D and Quality assurance team.

-

Savita has been in the transformer oil business for the past close to 60 years and has contributed significantly to the evolution of technologies.

-

Savita’s technical team participated in national and international standard committees (e.g.IEC & Cigre committees), presented papers at international conferences, collaborated with OEMs, Utilities and premier academic institutes and generally has a big presence in this important product line. The R&D head of Savita has recently published a book on the topic TRANSFORMER OIL APPLICATION ASPECTS, which is published by a reputed publisher in Europe.