Image for illustrative purposes

ASSET HEALTH MONITORING SOLUTIONS FOR POWER GRID EQUIPMENT

-

Power transformers and HV switchgear are usually the most valuable assets in a substation, requiring proper monitoring and maintenance.

-

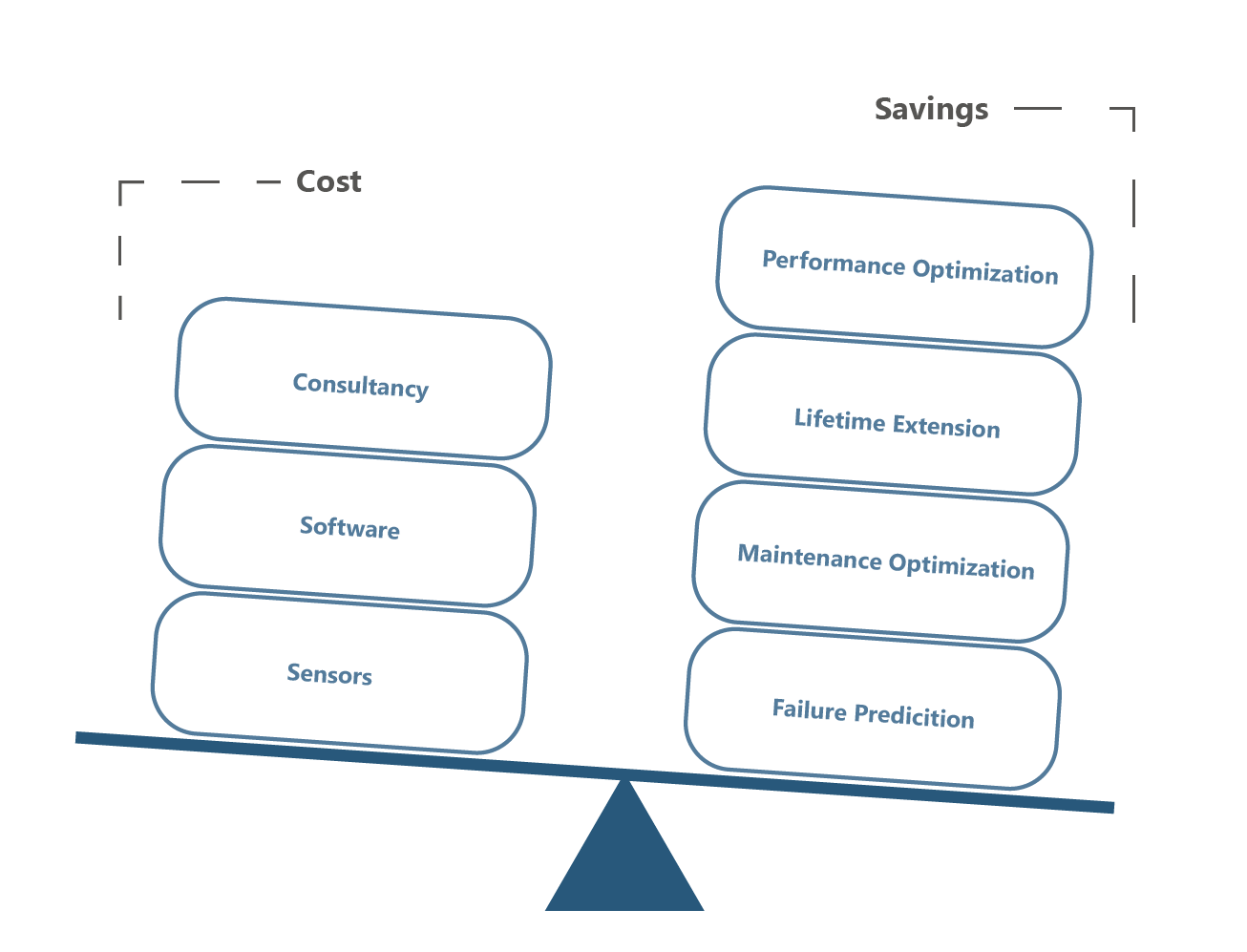

Cost-benefit analysis is a vital tool that helps electric utility companies, regulators, and grid operators in making informed investment decisions.

-

In the coming years, asset health monitoring is expected to become a key focus of utilities on a global scale.

Power transformers and HV switchgear are usually the most valuable assets in a substation, requiring proper monitoring and maintenance. Therefore, optimizing the life of an aging transformer and HV switchgear equipment is a major cause of concern for utilities and industries that have a significant installed base of transformers and HV switchgear. In some cases, this equipment dates back to the 1950s, and, ergo, needs to be consistently monitored through asset health monitoring (AHM) solutions that ensure optimum network performance and longevity.

Cost-benefit analysis is a vital tool that helps electric utility companies, regulators, and grid operators in making informed investment decisions. When it comes to the cost-benefit analysis of installing AHM solutions for costly electricity grid equipment, such as power transformers and HV switchgear, savings outweigh the associated costs. That is precisely why electricity grids in advanced economies, that can afford the upfront investment cost, are opting for AHM solutions and are reaping the benefits in terms of improved network reliability standards.

AHM solutions help save money by optimizing performance/maintenance, extending the life of the equipment, and predicting failure. Associated costs with AHM solutions include consultancy fees, the cost of software, and sensors.

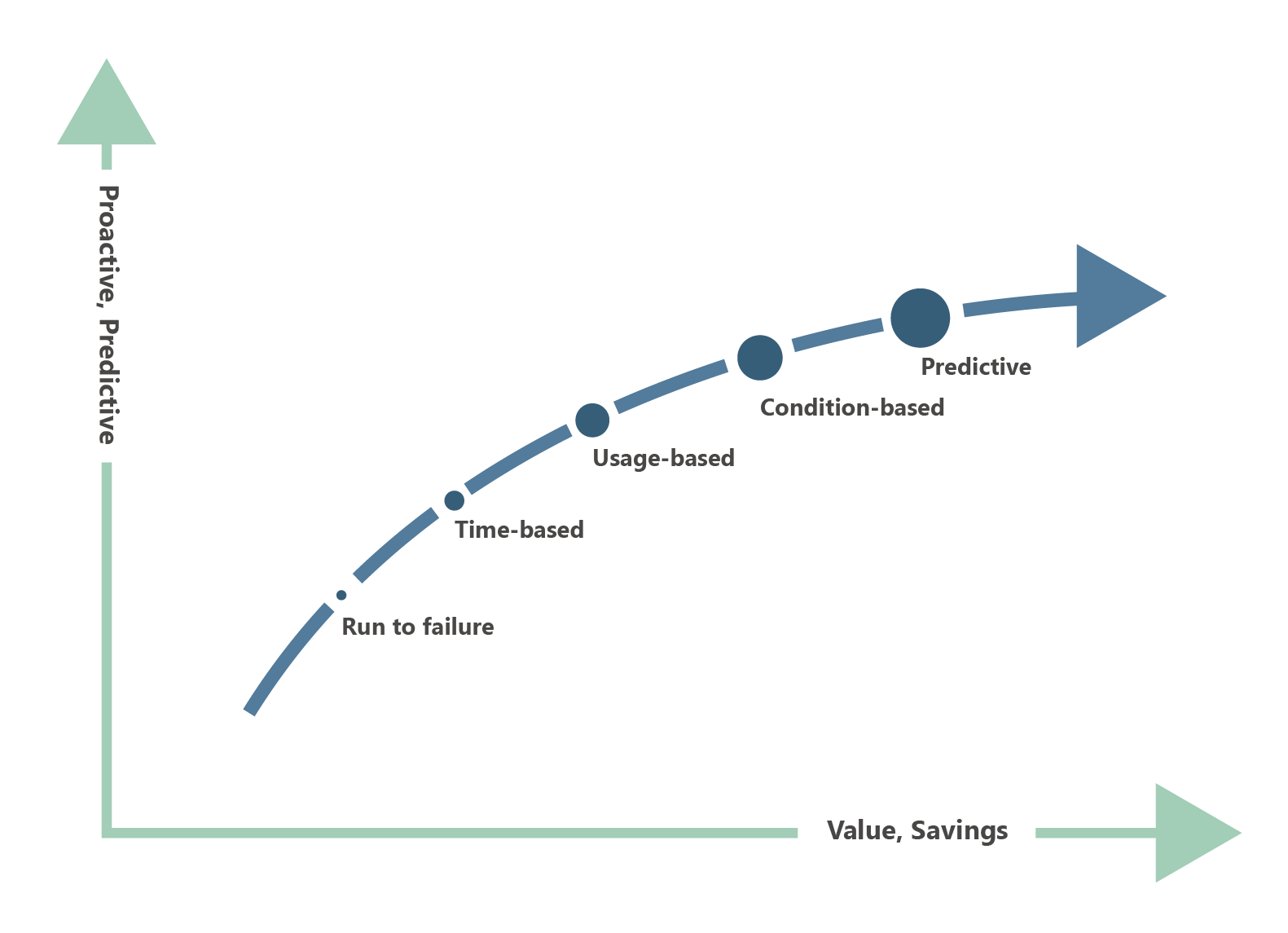

There are usually five maintenance strategies that are adopted for an electric grid asset in the maintenance industry, namely: run to failure, time-based, usage-based, condition-based, and predictive maintenance. Power Technology Research believes that, as the maintenance strategies for HV switchgear and power transformers shift towards condition-based and predictive maintenance, savings can be increased significantly (through life extension and optimized performance).

Figure 1: Maintenance strategies for an electrical grid asset.

Source: PTR Inc.

Features of Asset Health Monitoring

The major features of an asset health monitoring solution for HV switchgear and power transformers include reliability, efficiency, and future-proof investment. These are discussed below in detail.

Figure 2: Cost benefit analysis of AHM solutions.

Source: PTR Inc.

Reliability

1) Carries out the monitoring and diagnosis of the asset in real-time, focused on preventing forced outages and failure of equipment with timely warnings.

2) Enhances the integrity of equipment through condition-based and predictive maintenance.

3) With remote access and online asset management facilities, the exposure of human resources to substation environment may be reduced, therefore improving safety.

Efficiency

1) Improves the performance and increased utilization of the asset by converting information into actionable intelligence.

2) Reduces the total cost of ownership of the grid asset.

3) Provides dynamic fleet management and benchmarking.

4) Active network management capabilities for deeper renewable penetration in the energy mix.

5) Caters to the fluctuations in the grid in an intelligent manner, with a short response time.

Future-proof investment

1) New industry-standard: digitally integrated and ready to connect.

2) Modular and scalable platform with the full ecosystem of smart devices, software, and service solutions.

3) Building block for digital substations and state-of-the-art cyber security.

Product Portfolio and Case Studies

As far as the product portfolio of digital transformers is concerned, it is significant to note that a digital transformer is not a product in itself, but a solution that requires the integration of existing transformers with physical sensors and a digital platform. For instance, when the existing power transformer (from Hitachi ABB or any other manufacturer) is integrated with TXpertTM Ready Sensors (from Hitachi ABB or any other manufacturer) and with TXpert Hub (Hitachi ABB), it becomes TXpert enabled.

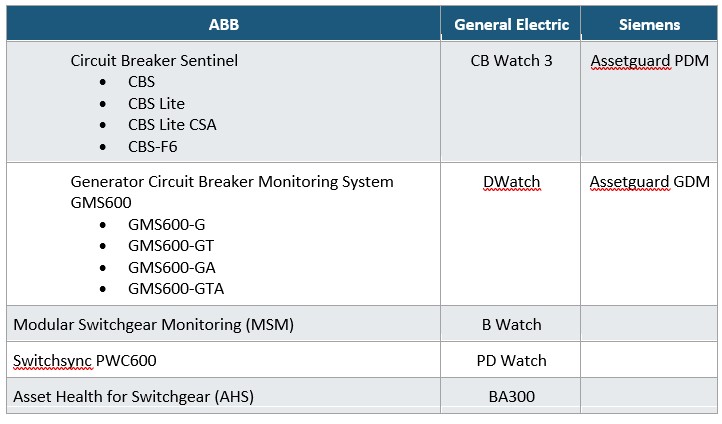

The product portfolio of AHM solutions for HV switchgear is given in the figure below. This suggests that the product range offered by ABB and General Electric is greater than Siemens, which only offers two products (Assetguard PDM and Assetguard GDM).

Figure 3: Product portfolio of asset health monitoring solutions for HV switchgear.

Source: PTR Inc.

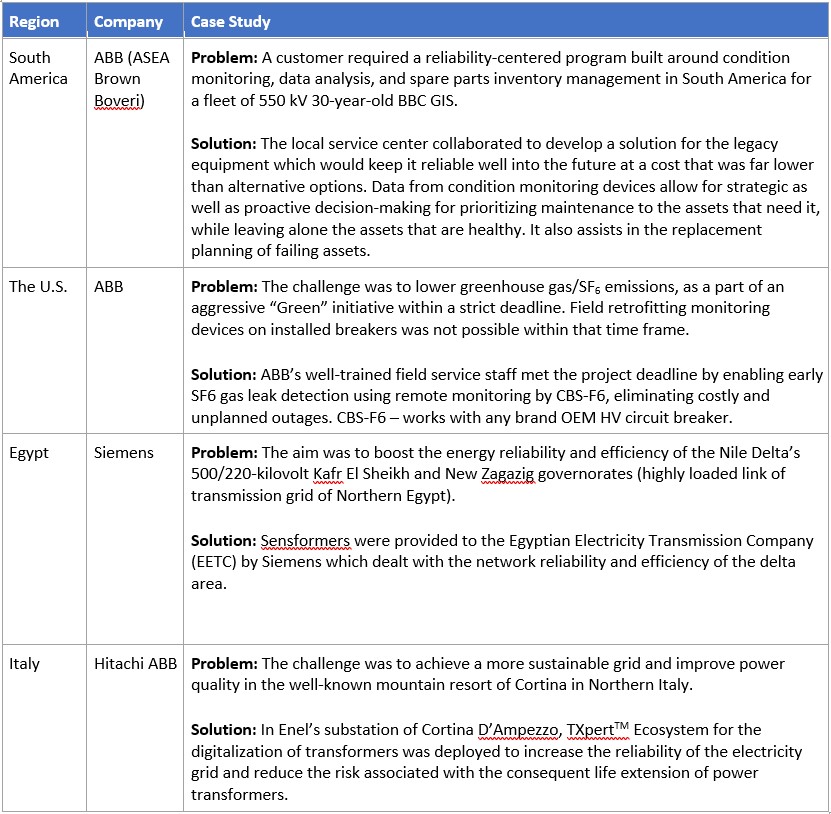

Several case studies, illustrated in Figure 4, explain how the deployment of asset health management solutions for HV switchgear and power transformers in various parts of the world has improved electricity network reliability.

Figure 4: Case studies of AHM solutions for HV switchgear and Power Transformers.

Source: PTR Inc.

Looking Ahead

In the coming years, asset health monitoring is expected to become a key focus of utilities on a global scale. This is especially true for advanced economies that can afford to make a significant initial investment in AHM solutions. Power Technology Research carried out a Europe-wide study of 35 transmission system operators in order to establish a relationship between network reliability indicators and the adoption of AHM solutions. It was observed that countries that have better network reliability indicators, such as lower SAIDI (System Average Interruption Duration Index) or SAIFI (System Average Interruption Frequency Index) values, were actually more inclined towards the adoption of digital solutions for AHM.