PARTIAL DISCHARGE MONITORING

One of the earliest indicators that high voltage electrical assets are beginning to degrade is the presence of partial discharges. IEC60270 defines partial discharge as a localized electrical discharge that only partially bridges the insulation between conductors, and which can or cannot occur adjacent to a conductor. Partial discharges can take several forms:

- Void discharges occur in defects in the solid insulation. The discharges occur because the breakdown strength of the void is much lower than the breakdown strength of the solid insulation around it. Void discharges typically occur in cables, bushings, and transformers. Void discharges can be highly destructive to insulation and in time will typically result in complete failure of the insulation.

- Surface discharges occur along the surface of insulation rather than in voids in the insulation. Repeated surface discharges will often result in surface tracking which is easily seen by the eye. Surface discharges can occur in air insulated switchgear, on the external weather sheds of insulators and bushings, and in motors and generators. Surface discharges can significantly increase in the presence of surface contamination, humidity, fog, and light rain

- Corona discharges occur when the air surrounding a conductor carrying high voltage becomes ionized allowing the charge to continuously bleed off the conductor into the air. Corona often radiates from sharp surfaces or irregularities on the surface of the conductor.

- Arcing discharges are prolonged electrical discharges produced by the electrical breakdown of a gas. Plasma is an example produced when current flows through air, or any other normally non-conductive medium.

Partial discharges (PDs) can pose a significant threat to high voltage electrical equipment. Partial Discharge is also typically the first indicator that an electrical asset is degrading. If left undetected or if corrective actions are not taken, partial discharges can lead to costly electrical failures. Thankfully, technologies exist which allow the detection of partial discharges in energized electrical equipment. PD cannot be measured directly, however, its energy by-products such as electrical transients, electromagnetic emissions, sound, light, and heat can be measured. Of these, the monitoring of electrical transients (i.e. electrical partial discharge monitoring) is the easiest and most cost effective to implement continuously online. Electrical partial discharge monitoring also offers the ability to utilize a single sensor for both bushing monitoring as well as online partial discharge monitoring.

Partial Discharge is typically the first indicator that an electrical asset is degrading.

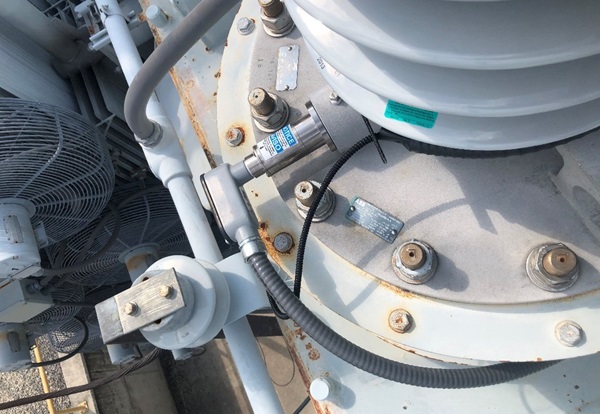

As part of a comprehensive online monitoring program, an electrical utility installed key gas DGA, bushing and partial discharge monitoring on their generator step up transformers. The bushing and PD system consisted of sensors installed in the test taps of the high voltage bushings, Rogowski coils installed around the porcelain skirt closest to the bushing flange, and coupling capacitors connected to the bolted connections of the flexible links connected to the LV bushings. Coupling capacitors were used to monitor the LV winding of the transformer since the LV bushings did not have test taps. Pictures of the monitoring system and sensor installations are provided in figures 1 and 2.

Figure 1 - Dynamic Ratings Comprehensive Transformer Monitoring System

Figure 2 - Bushing and Partial Discharge Sensor Installed on a GSU

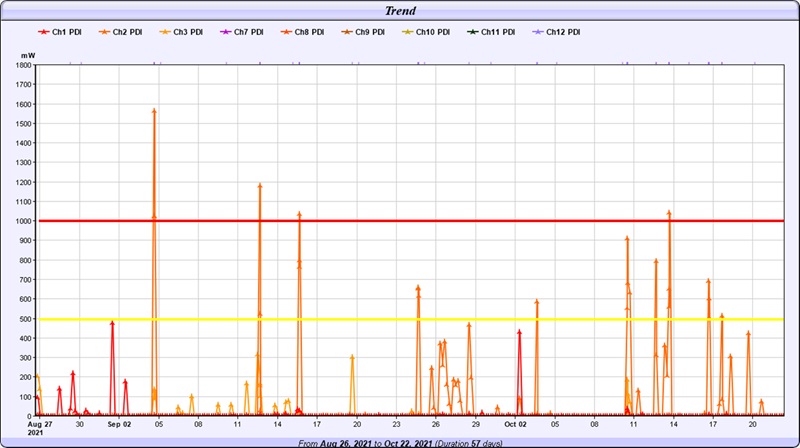

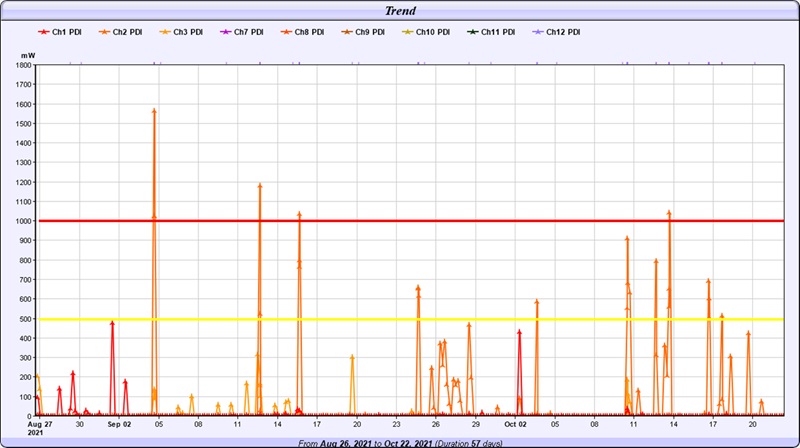

Shortly after the monitor was installed, the customer began receiving alarms due to high levels of partial discharge intensity. Partial discharge intensity is an estimate of the energy of the partial discharge. The trend chart shown in figure 3, shows that the partial discharge intensity from all sensors was acceptable except for periodic spikes associated with activity on channel 2 of the monitor which exceeded the warning and alarm thresholds.

Figure 3 - Trend of the partial discharge intensity

Figure 4 shows the Phase Resolved Data plots of the partial discharges on the HV side of the tranformer. The phase resolved data patterns can be used to identify the type of partial discharges that are occurring. The patterns shown in figure 3 are not typical of patterns associated with partial discharge in the insulation system of the transformer and are consistent with discharges coming from outside the transformer. In addition, since the patterns are being detected by sensors on different phases and there are discharges appearing on various parts of the waveform, this is an indication that the discharges are coming from multiple sources.

Figure 4 - Phase resolved data patterns of the partial discharges

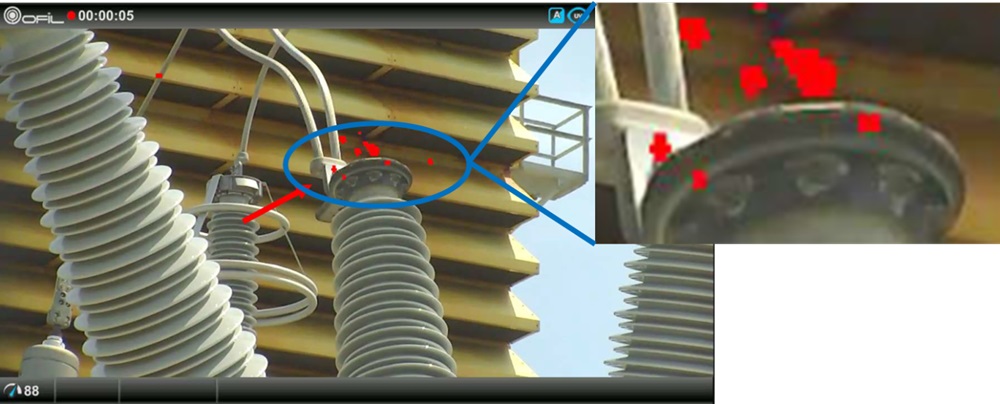

Since the analysis identified that the discharges were coming from outside the transformer, Dynamic Ratings recommended that the customer scan the high voltage yard with a corona camera. Using the corona camera, the customer was able to identify multiple sources of partial discharges. The most concerning problem was an issue that was identified with the bushings on the high voltage SF6 breaker protecting the transformer. Large amounts of partial discharge were eminating from the bushing cap and a visual inspection of the bushing cap identified corrosion problems on this bushing as well as 12 other GCB bushings in the plant. As a result of the partial discharge monitoring and the follow up corona camera inspections, the customer contacted the breaker manufacturer to perform a visual inspection of the HV gas circuit breakers. The manufacturer has recommended the replacement of 12 bushings on the GCB’s protecting the transformers.

Since the analysis identified that the discharges were coming from outside the transformer, Dynamic Ratings recommended that the customer scan the high voltage yard with a corona camera.

Figure 5 - Corona camera image of the transformer HV SF6 breaker

Online condition monitoring of high voltage electrical equipment is an effective way to identify degrading electrical assets at an early stage. Utilizing a comprehensive approach allows utilities to implement technologies to identify and prevent nearly all failure modes typically found in their high voltage electrical assets. While technologies like DGA and online bushing monitoring have been used for years to identify degrading high voltage electrical assets, implementation of online partial discharge monitoring is not as common. However, since partial discharge is typically the first indicator that an electrical asset is degrading, it makes sense to include partial discharge monitoring as part of a comprehensive approach to monitoring your high voltage assets.

Online condition monitoring of high voltage electrical equipment is an effective way to identify degrading electrical assets at an early stage.

- IEC 60270 High Voltage Test Techniques – Partial Discharge Methods

- IEEE C57.127 Guide for Detection, Location and Interpretation of Sources of Acoustic Emi9ssions from Electrical Discharges in Power Transformers and Reactors

- IEEE C57.143 IEEE Guide for Application for Monitoring Equipment to Liquid-Immersed Transformers and Components

Mark Tostrud is the Technology Officer for Dynamic Ratings, Inc. located in Sussex, Wisconsin. He joined Dynamic Ratings in the fall of 2006 and has been instrumental in helping Dynamic Ratings customers incorporate online monitoring into their condition-based maintenance programs. Mark’s goal is to improve the understanding of the technologies and analytics the monitors offer so customers can get the most out of their monitoring systems, improve their system performance and make better asset management decisions.

Prior to his present position, Mark was a Construction & Maintenance Supervisor at We Energies. During his 19 years at We Energies, Mark lead the implementation of many of condition-based monitoring programs for substation equipment. Mark is a past officer of the Doble Oil Committee, and was an active member on various Doble Committees and Subcommittees including the Transformers, Insulating Materials, DGA of LTCs and others.

Mark is a registered professional engineer in the State of Wisconsin.

Powered by