Image for illustrative purposes.

Over the years the demand for electricity has increased across the globe, which has in turn created the need for a more efficient and reliable eletricity grid. The demand for improved reliability and efficiency applies to electrical bushings as well, which has pushed for innovation in bushing technology. Although a bushing may seem like a hollow piece of porcelain that contains a conductor, the task it performs is quite extraordinary. In order to insulate the high voltage conductor, bushings are installed so that flashovers due to ionization of nearby air or gas can be avoided. Other than providing critical electrical insulation, bushings provide support to high voltage connections and assist in managing the thermal stresses that usually occur in high-voltage environments.

PTR Inc. has observed that original equipment manufacturers of bushings have improved the efficiency and reliability of bushings through advancements in materials, design, and manufacturing processes over the years. It is noteworthy that utilities across the globe can prevent equipment failure, reduce downtime and safety hazards for employees and consumers through investment in high quality bushings.

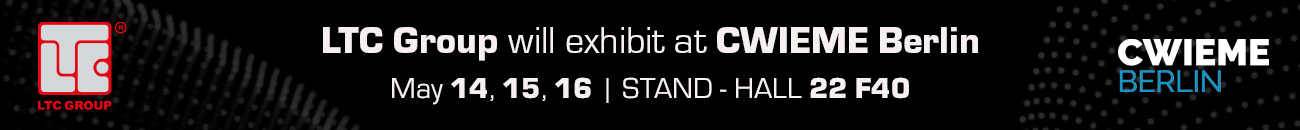

Figure 1: Applications for Bushing

Source: PTR Inc.

Developments in the Bushing Industry

PTR Inc. believes that bushing technology is consistently evolving as OEMs introduce new materials (nanocomposites and silicon carbide), improve design and manufacturing processes with computer aided design and finite element analysis, and embed sensors in the bushings to make them smart.

New materials for bushings

Bushing manufacturers have introduced new materials, for instance nanocomposites and silicon carbide, which have improved the performance and increased the lifespan of bushing. In nanocomposite materials, embedded nano-sized particles in a polymer matrix increase the strength of materials such that these materials are more resistant to high temperatures.

In nanocomposite materials, embedded nano-sized particles in a polymer matrix increase the strength of materials such that these materials are more resistant to high temperatures.

On the other hand, silicon carbide has high thermal conductivity which enables improved heat dissipation in turn reducing the risk of overheating and failure. If compared with porcelain, bushings made with nanocomposites or silicon carbide are durable, perform better and are suited for use in harsh environments.

Furthermore, environmental factors such as temperature, humidity, pollution, and corrosive agents in the atmosphere are detrimental for the performance and durability of bushings. The newly developed materials and advanced coatings are significantly more resistant to aforementioned environmental factors. It is worth noting that Tier-1 OEMs are using nanocomposites in their resin-impregnated paper bushings. Also, Siemens’ silicon carbide bushings have been installed in renewable energy projects.

Improved design and manufacturing processes

In order to optimize the design of bushings, certain companies, for instance GE Grid Solutions and CTC Global, use computer aided design and finite element analysis. Use of CAD and FEA has ensured better performance and reliability in bushings. CAD allows the designers to visualize and simulate the electrical bushing in a 3D environment, which in turn paves way for more efficient design and reduces the risk of errors. On the other hand, FEA provides the ability to simulate how the bushing will behave under different loads. These simulations assist the manufacturers in gauging if the bushing will be able to withstand high stresses.

In order to optimize the design of bushings, certain companies, for instance GE Grid Solutions and CTC Global, use computer aided design and finite element analysis. These simulations assist the manufacturers in gauging if the bushing will be able to withstand high stresses.

Image for illustrative purposes

Smart bushings with monitoring and diagnostic capabilities

Hitachi ABB Power Grids and Trench Group are working to develop smart bushings that are equipped with state-of-the-art monitoring and diagnostic capabilities. System operators make use of the sensors embedded in the bushing to monitor different parameters, for example temperature, pressure, and vibration. On other hand data, analytics is deployed to analyze the data collected through different sensors in turn enabling predictive maintenance and reduce the risk of unplanned downtime. It is noteworthy that this technology is particularly useful in remote or hard-to-reach areas, where carrying out regular maintenance is difficult.

Some bushings in the market are also equipped with advanced cooling and self-cleaning technologies that assist them in managing thermal stresses, detect moisture buildup, prevent buildup of pollutants, and protect against corrosive agents. Such innovations have positively impacted the performance and reliability of electrical bushings.

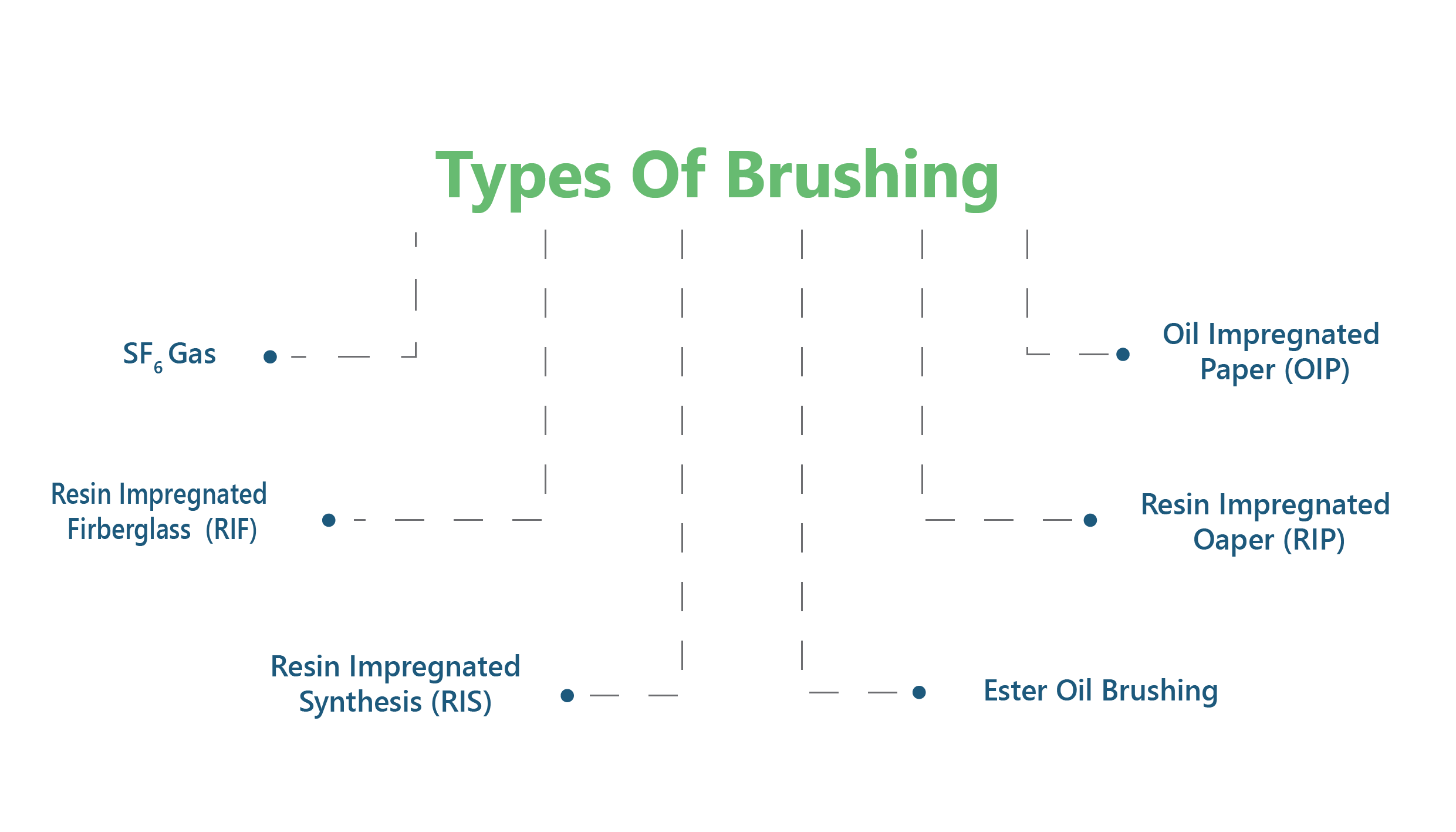

Figure 2: Types of Bushing

Source: PTR Inc.

Successful bushing installations

Several renewable energy projects have installed ABB’s silicon carbide bushings which has improved reliability and reduced maintenance cost of the project. On the other hand, Siemens has achieved similar outcomes in terms of improved reliability and reduced maintenance costs by installing nanocomposite bushings in electrical trains. Additionally, Dubai Electricity and Water Authority has installed Trench Group’s smart bushings in its electrical network. All of these installations highlight the impact that innovation in the bushing’s technology can have on the electricity grid.

Future Outlook

Following the Paris Agreement in 2016, economies all over the world have pushed for the deployment of renewable energy and . PTR Inc. believes that as the renewable energy and electric vehicle become more prevalent in the global energy market, the need for improvements in the performance and reliability of electrical systems will also increase which would in turn render the innovation in the bushing technology more critical.

Innovations in recent years in bushing technology including the introduction of new materials, improvements in design and manufacturing, and incorporation of sensors with conventional bushings, have improved the performance and durability of electrical bushings. The improvements in the performance and durability of electrical bushings have in turn benefited the global electrical industry. PTR Inc. believes that the global electrical industry is evolving and with it the performance and reliability requirements are also changing so only those OEMs will be able to increase their market share in future that are able to cater ever evolving requirements.