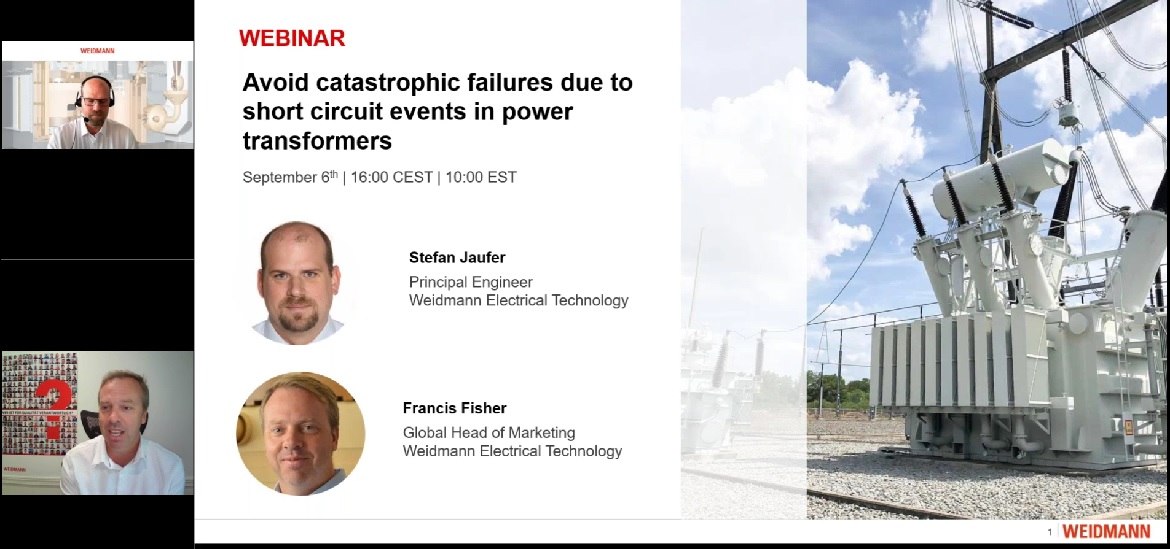

The Weidmann Engineering Services Team explain a project which examines the history and development of on-line monitoring of clamping forces in power transformers.

The project addresses the impact of short circuit events and the requirement for tight clamping of transformer windings. The Clamping Force Sensor works by measuring temperature and core mechanical stresses by using a system of small ‘mirrors’ in the fiber core, capable of monitoring even small changes in clamping pressure.

This project has been selected by Weidmann due to feedback from transformer manufacturers about the challenges of tight clamping of power transformer windings and the requirement to withstand forces which occur during short circuit events. The challenge we set up the project to overcome, is to provide a way to maintain the conductors and windings at their designed positions/locations, taking into account that, during assembly, the clamping force can deviate significantly from the designed value, and even more so during operation.

As well as the Clamping Force Sensor monitoring clamping pressure and temperature changes notifying the user of any changes to the winding pressure and thus avoiding catastrophic short circuit events, monitoring of clamping force during service may also be used to improve transformer reliability.

Unlock the knowledge you missed! Click here to catch our webinar now!

To download a copy of the presentation Click here!